News Room

Potassium Management in P&P Recovery Cycles

October 2, 2015

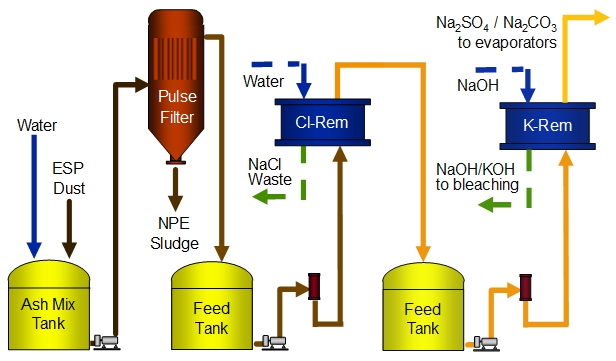

A new technology package from NORAM uses ion-exchange technology for purging both chloride and potassium in the chemical recovery cycle of kraft and soda pulp mills. The issue of potassium build-up, which can manifest as a constraint on recovery boiler operation, has, until now, limited the ion exchange technology to those applications requiring chloride management alone. The PDP-K™ system takes the successful PDP™ (Precipitator Dust Purification) platform commercialized by NORAM, to the next level.

The PDP™ technology has enjoyed strong industry uptake for the removal of chloride from electrostatic precipitator dust and thereby reducing chloride concentrations throughout the chemical cycle. The technology, based on Eco-Tec’s Recoflo® ion-exchange technology, quickly distinguished itself for ease of operation and very low chemical losses. Eight mills have purchased PDP™ systems in North and South America.

Development work over several years has added another stage to the PDP™, based on technology successfully implemented at three mills in Japan by Nippon Rensui Co. The traditional advantages of PDP™ are maintained, while greatly extending the adaptability of the technology.

© 2025 NORAM Engineering and Constructors Ltd.