News Room

Growing the Electrochemical Value Chain

February 1, 2023

Two leading Canadian innovators are collaborating successfully to advance the Canadian electrochemical supply chain. A Memorandum of Understanding between Vancouver, BC companies NORAM Electrolysis Systems Inc. (NESI) and Ionomr Innovations Inc. provides for the initial testing of Ionomr’s advanced anion exchange membranes in NESI’s proprietary NORSCAND® electrolysis platforms for critical salt-splitting applications.

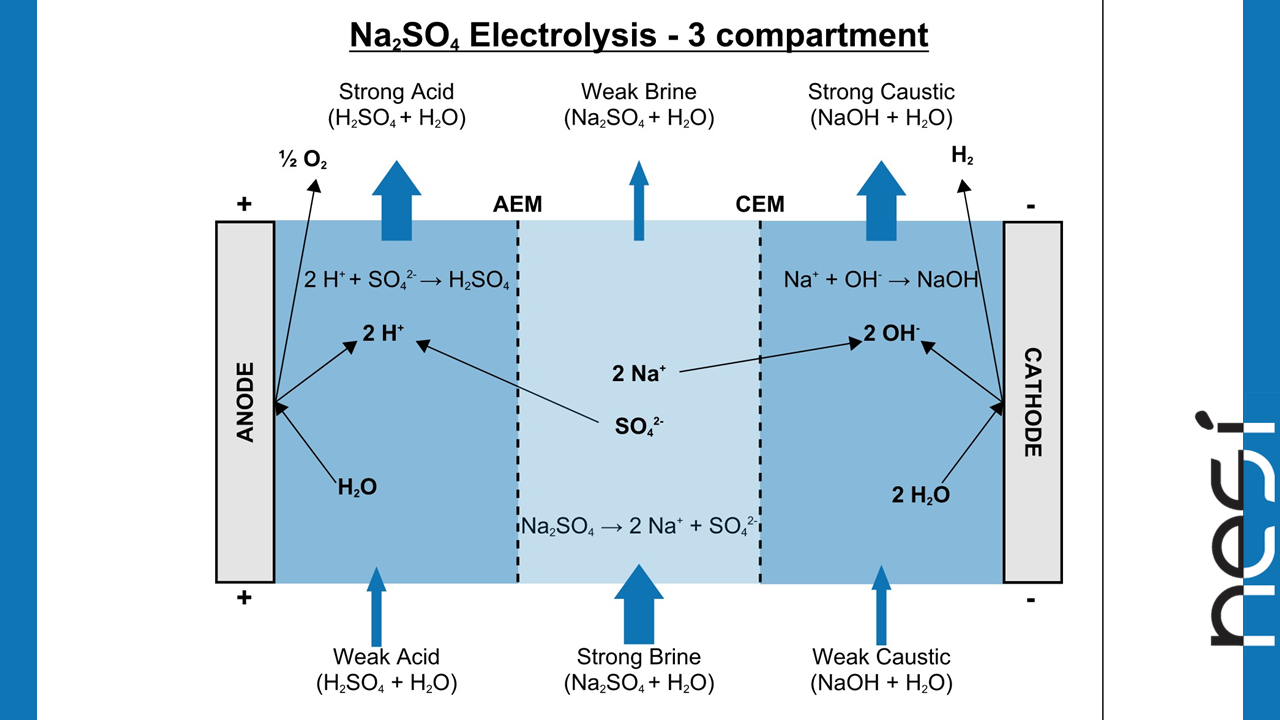

The electrochemical production of high-purity Lithium from diverse brines and mineral resources is increasingly seen as a key building block in the rapidly growing Lithium Ion Battery (LIB) industry. Electrolysis allows the effective conversion of lithium precursors to the desired lithium hydroxide chemicals that enter battery use. It moreover represents a feasible pathway in the circular economy to re-processing by-products such as sodium sulphate into useful chemicals such as NaOH and H2SO4.

Ionomr has specialised in the development of durable, high-performance Anion Exchange Membranes (AEM), that allow longer lifetimes in both highly basic and strongly acidic environments. Ionomr’s AEM, called Aemion®, does not use perfluorosulfonic acid (PFSA) materials that are increasingly being discontinued worldwide due to environmental concerns. Hydrogen producers across the globe are also developing Aemion® technology in their systems. Small-scale validation testing with NESI in Q1 2023 is expected to validate the application of Aemion® for industrial salt-splitting processes.

© 2025 NORAM Engineering and Constructors Ltd.