News Room

Breakthrough for Brazil Pulp Industry

October 18, 2011

A pulp mill in Brazil has become the fourth beneficiary of the very successful Precipitator Dust Purification (PDP™) system introduced by NORAM to the P&P industry. The unique ion-exchange system purges metal chlorides from the Kraft mill recovery cycle, that otherwise result in sticky deposits in the recovery boiler, and constrain overall mill production.

Brazillian mills are typically large modern facilities, requiring chloride removal systems that can accommodate large dust throughputs. A PDPTM system can accommodate up to 320 tonnes/day of precipitator dust in a single ion-exchange bed.

The high chloride inputs associated with plantation Eucalyptus, taken together with very expensive sodium sulphate for chemical make-up, make selective chloride recovery an especially important proposition in Brazil.

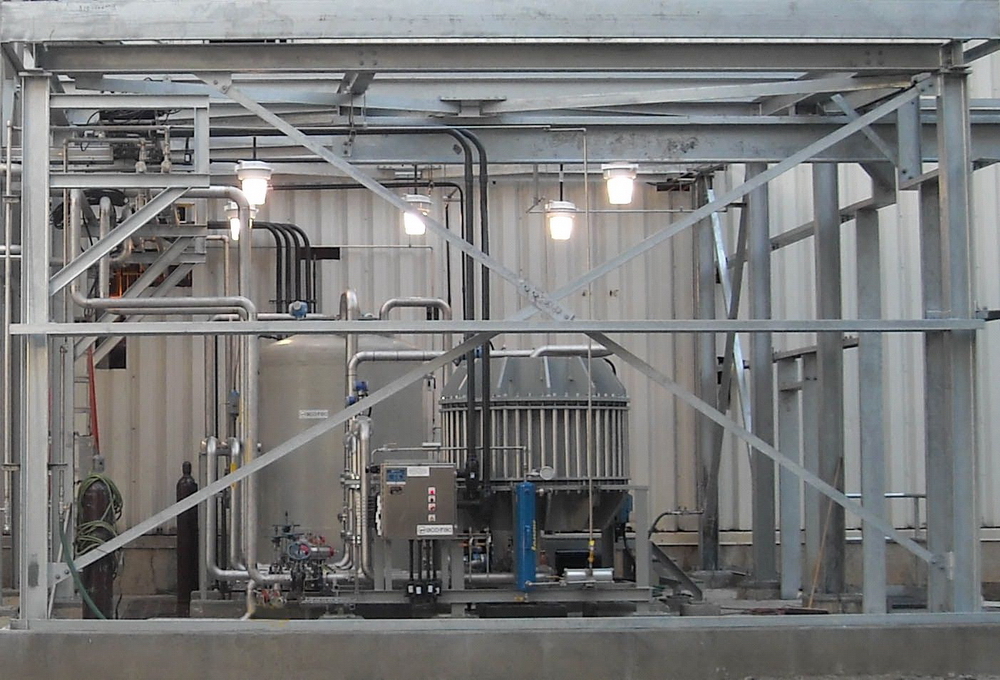

Rapid delivery of these shop-tested modular units and minimal installation requirements allow mills to implement the low-cost system within 6 months from order. In operation they provide efficient chloride removal with the lowest soda losses verified in the industry. A 75 tpd PDP™ Chloride Removal Ion Exchange System based on the versatile RecoFlo™ platform manufactured by Eco-Tec Inc. is shown here.

© 2025 NORAM Engineering and Constructors Ltd.